Dehydrated Castor Oil

Dehydrated Castor Oil Specification

- Raw Material

- Castor Seeds

- Grade

- Industrial Grade

- Refined Type

- Refined

- Usage

- Industrial applications, paints, varnishes, inks, and coatings

- Packaging Size

- 190 kg drum, 50 kg carboy

- Shelf Life

- 24 months

- Application

- Surface coatings, adhesives, sealants

- Product Type

- Dehydrated Castor Oil

- Type

- Vegetable Oil

- Processing Type

- Dehydration

- Use

- Alkyd resin, printing, synthetic rubber

- Purity(%)

- 98%

- Iodine Value

- 125-135

- Hydroxyl Value

- <10 mg KOH/g

- Moisture

- <0.2%

- Insoluble Impurities

- <0.02%

- Acid Value

- 2-6 mg KOH/g

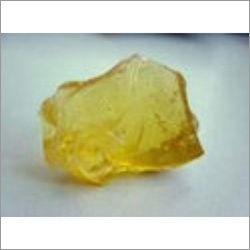

- Appearance

- Clear pale yellow liquid

- Saponification Value

- 179-190 mg KOH/g

About Dehydrated Castor Oil

Dehydrated Castor Oil is by far the most important coating. In commercial manufacture the oil is now known as an individual drying oil. Its advantages claimed in different surface coating applications such as excellent odor and heat bleachability, superior drying properties, uniform polymer structure, and lack of after-yellowing. Dehydrated Castor Oil can be used to enhance the quality of house paints, sealants, caulks, & inks. It is used as basic binder for house paints, caulk sealant, enamels, & making varnishes.

| Type | Chemical |

| Purity | 99% |

| Appearance | Liquid |

Optimal Performance for Industrial Applications

Dehydrated Castor Oil is a staple ingredient in the manufacture of paints, varnishes, and surface coatings due to its superior drying and film-forming properties. Its stable viscosity and refractive index make it an ideal choice for applications demanding clear finishes and lasting protection, contributing to the durability and aesthetic appeal of various industrial and decorative surfaces.

Quality and Storage Assurance

The oil is characterized by a pale yellow appearance and low levels of moisture and impurities, ensuring product consistency. Proper storage in a cool, dry environment away from direct sunlight preserves its chemical stability and extends its shelf life to 24 months. This attention to quality allows industries to rely on its performance and purity for long-term projects and bulk manufacturing processes.

FAQs of Dehydrated Castor Oil:

Q: How should dehydrated castor oil be stored to maintain its quality?

A: Store dehydrated castor oil in a cool and dry place, away from direct sunlight, as prolonged exposure to heat or light can compromise its chemical stability and reduce its shelf life.Q: What are the primary industrial applications of dehydrated castor oil?

A: Dehydrated castor oil is predominantly used in manufacturing alkyd resins, paints, varnishes, printing inks, synthetic rubber, coatings, adhesives, and sealants, thanks to its excellent drying properties and film-forming abilities.Q: When is dehydrated castor oil preferred over regular castor oil in formulations?

A: It is preferred in applications requiring enhanced drying speed and clarity, such as surface coatings and varnishes, where regular castor oil does not provide the same level of performance and finish.Q: Where is dehydrated castor oil typically exported or manufactured?

A: Dehydrated castor oil is widely exported and manufactured in India, where suppliers and manufacturers adhere to industrial-grade specifications and international standards.Q: What is the process involved in producing dehydrated castor oil?

A: The oil is processed by dehydration of refined castor seed oil, which reduces its hydroxyl value and moisture content, resulting in a clear pale yellow liquid with improved drying characteristics for industrial use.Q: How does using dehydrated castor oil benefit paint and coating formulations?

A: Its high purity, low moisture, and tailored viscosity ensure a uniform application, rapid setting, and robust protective layers, enhancing durability and visual appeal of the finished surfaces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Castor Oil BP Category

Castor Oil BP 98 Pharmaceutical Grade

Saponification Value : 176 187 mg KOH/g

Application : Pharmaceutical & Cosmetic Industry

Appearance : Pale yellow, clear oily liquid

Insoluble Impurities : Negligible

Use : Other, Pharmaceutical grade applications

Iodine Value : 83 88

Blown Castor Oil

Saponification Value : 175 185 mg KOH/g

Application : Paint, Ink, Lubricant, Emulsifier, Plasticizer

Appearance : Clear, Viscous Liquid

Insoluble Impurities : <0.1%

Use : Other, Plasticizer, Paint, Polymer, Soap

Iodine Value : 7585 (g I2/100g)